Manual Metal Arc Welding (MMAW) welding (weldingwelder.blogspot.com)

. Introduction

Manual Metal Arc Welding (MMAW) is one the earliest of the arc welding processes,

but has remained popular despite the introduction of newer and more sophisticated

processes. Indeed, this lack of sophistication is one of the major attractions of the

process.

In this chapter you will look at the following.

. The process

. applications

. advantages

. limitations

. Equipment

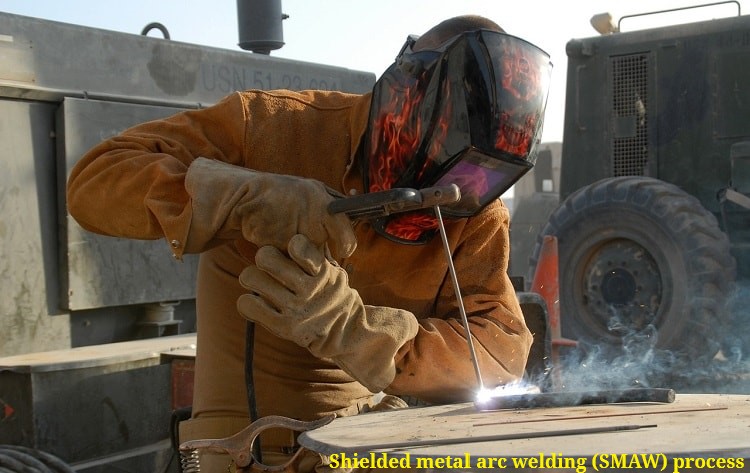

. The process Manual Metal Arc Welding (MMAW)

The MMAW process operates as follows.

A low voltage, high amperage current flows to create an arc between the tip of the

electrode and the work piece. This generates the heat for welding and causes the work

piece and the tip of the electrode to melt.

The flux coating on the electrode decomposes (burns) due to the intense heat of the

arc and generates a gaseous shield, which protects the weld pool and surrounding hot

metal from the atmosphere.

The electrode melts off and is transferred across the arc in the form of droplets. The

molten metal provided by the electrode adds to the molten parent metal and they

become the weld metal when solidified.

Molten electrode flux which is transferred across the arc acts as a scavenger, picking

up impurities from the surface of the parent metal. The slag which forms covers the

weld pool, solidifies, and protects the hot weld metal as it cools.

The flux ingredients provide arc ionisation (the air gap between the tip of the electrode

becomes electrically conductive), enabling the use of alternating current.

. Applications of the process Manual Metal Arc Welding (MMAW)

Many welding operators have grown up using the MMAW process. This familiarity

and the fact that it is simple to set up and use, makes it first choice for selection in

many instances. The low cost of equipment makes the process accessible to most

people, and MMAW has no special requirements such as external gas shielding or

high-frequency arc initiation. Sound welds are easily produced and the process doesn’t

tend to result in weld defects such as lack of fusion which is common in GMAW.

MMAW is widely used for: welding (weldingwelder.blogspot.com)

. structural work

. pressure vessels

. piping

. maintenance welding

. site construction

. general fabrication.

. Advantages of the process Manual Metal Arc Welding (MMAW)

The advantages of the MMAW is its versatility and the availability of a wide range

of consumables. Set-up time is short, making the process ideal for small jobs, short

production runs, and where the welding is carried out on site.

MMAW offers the following advantages over other welding processes:

. low capital cost for equipment

. versatility across a wide range of applications

. simple, reliable equipment

. low maintenance of equipment

. ideal for site work

. wide operator appeal

. sound, reliable welds.

welding (weldingwelder.blogspot.com)

. Equipment Manual Metal Arc Welding (MMAW)

Equipment for manual metal arc welding consists of the following.

. Power source – usually a constant-current type output transformer or transformer

rectifier is used, although various other types of power sources, such as

generators or inverters can also be used. The function of the power source is to

supply welding current with sufficient amperage to provide the necessary heat, at

a voltage which is safe to use.

. Electrode handpiece and lead – to carry current to the arc via the electrode.

. Work return lead – connects the work piece to the power source thereby

completing the welding circuit. (A closed circuit is necessary for current flow).

Limitations of the process Manual Metal Arc Welding (MMAW)

. Although faster than some welding processes, MMAW has lower deposition rates than

many of the newer welding processes that use a higher current. The process has a

low operator duty cycle, with the operator spending a lot of time changing electrodes

and chipping slag. These two factors combine to limit the application of this process,

especially if high production rates are required.