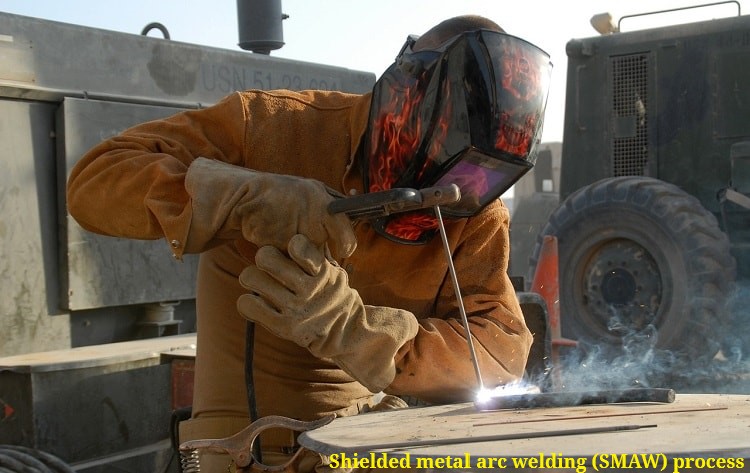

manual metal arc welding (MMAW)

. amperage

. arc length

. travel speed

. angle of approach

. angle of travel.

welding (weldingwelder.blogspot.com)

Amperage manual metal arc welding (MMAW)

. An increase in amperage will:

. increase the heat of the welding arc

. increase fusion and penetration

. give a higher deposition rate

. increase arc force

. enable easier arc starting

. give a more fluid weld pool

. increase spatter

. increase emission of ultra violet radiation.

A decrease in amperage will have the opposite effect.

As the size and thickness of the metal to be welded increases, so the heat required for

fusion increases, necessitating higher amperages. Also the higher the heat input, the

slower the cooling rate of the weld zone. Slow cooling rates are generally desirable

when welding most metals.

A simple equation is: VOLTAGE x AMPERAGE = HEAT

Angle of approach manual metal arc welding (MMAW)

Another simple rule for welders is that the metal goes were you point the electrode.

Following that rule, it can be seen in the fillet weld example below that to get an even

weld build up, the electrode must be pointed evenly at both plates, ie 45° and the

welding arc is ‘directional’, that is metal transfer is essentially along the line of the

electrode.

Angle of approach

Another simple rule for welders is that the metal goes were you point the electrode.

Following that rule, it can be seen in the fillet weld example below that to get an even

weld build up, the electrode must be pointed evenly at both plates, is 45° and the

welding arc is ‘directional’, that is metal transfer is essentially along the line of the

electrode.

welding (weldingwelder.blogspot.com)

Angle of travel manual metal arc welding (MMAW)

The angle of travel is established essentially as a means of keeping the molten weld

pool behind the arc, and preventing the slag from catching up to the electrode and

causing slag inclusions. Although the angle of travel is commonly set at 60–70° many

factors such as amperage, electrode type, and travel speed will determine the actual

angle used. It should be noted however that the angle of travel used should be the

minimum required for slag control, as laying the electrode too flat causes problems

such as poor appearance, excessive spatter, reduced penetration, and a narrow,

convex bead shape

welding (weldingwelder.blogspot.com)