manual metal arc welding electrode types

The manual metal arc welding electrode consists of a core of wire surrounded by a flux coating. The wire is generally of similar composition to the metal to be welded. The flux is applied to the wire by the process of extrusion. For welding carbon and low alloy steels (the metals most commonly fabricated using the MMAW process) electrodes will have one of four flux types, either:

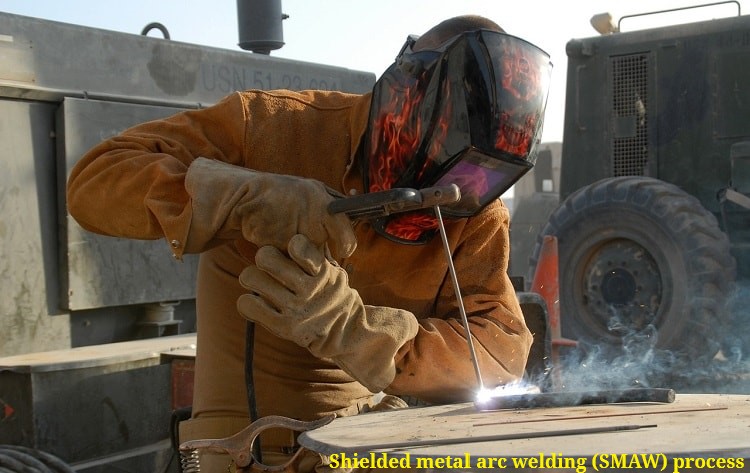

welding (weldingwelder.blogspot.com)

1.cellulose type coating

2.rutile type coating

3.hydrogen controlled coating (low hydrogen)

4.iron powder type coating.

The flux coatings (from which the electrode types take their name) account for the major differences between electrode types. The ingredients of the flux coating are carefully controlled so as to give desirable running characteristics and weld metal properties.

Among these desirable running characteristics are:

. arc stability

. ease of striking

. elimination of porosity

. minimum spatter

. elimination of noxious fumes and odours

. a tough durable coating

. control of penetration

. high deposition rates

. desirable physical and mechanical weld metal properties.

The aforementioned list is by no means exhaustive and many characteristics are incompatible, eg deep penetration and minimum spatter. Therefore when choosing an electrode for use, compromises must be made.

The choice of an electrode for a particular application depends upon:

. the composition of the parent metal

. the size and thickness of the parent metal

. the mechanical properties required of the weld metal

. the physical properties required of the weld metal

. the welding position

. the amount of penetration required

. the amount of spatter allowable

. available welding current

. deposition rate required

. appearance

. cost

. slag detachability

. weld contour and size

. fluidity of the slag

. operator appeal. welding (weldingwelder.blogspot.com)

Functions of the flux coating

In the early days of arc welding, bare wire electrodes were used. The results obtained from these electrodes left much to be desired. Over the years, electrodes have improved and flux coatings have evolved to the stage where the deposited weld metal, in many cases, has better metallurgical properties than the parent metal.

The flux coating of the electrode has many functions. It:

. provides a gaseous shield to protect the weld from atmospheric contamination

. provides arc ionisation. This gives a stable arc and enables the use of AC

. controls the chemical composition and properties of the deposited weld metal.

. controls the deposition rate

. controls spatter

. influences the degree of penetration

. provides slag which performs the following functions:

. forms a protective cover over the weld metal to prevent the formation of

. oxides while the weld metal is cooling

. acts as a scavenger to remove oxides and impurities from the weld

. helps to produce the correct bead shape and improve weld appearance

. slows the cooling rate of the weld metal

. enables ‘positional’ welding.

Some of the ingredients used in flux are:

. wood pulp (cellulose), titanium dioxide (rutile), limestone, fluorspar, silica, and

. feldspar – for producing slag and shielding gas

. ferro-manganese and ferro-silicon – used as deoxidizers

. potassium and sodium silicates, used as binders

. clays and gums – used as binders

. ferro-chromium, ferro-molybdenum and nickel powder – for alloying

. iron powder and iron oxide – to increase deposition.

welding (weldingwelder.blogspot.com)